Faster Egg Tray Production with Improved Production Process

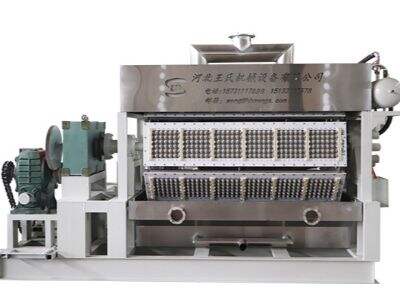

We make egg trays, it takes some time but we need to reduce this. Put differently, we would need to arrange our steps properly in other not to waste time. And, we can make egg trays much quicker and more effectively by putting our machines and materials in a series. This Egg tray production machine allows us to more creates egg trays quicker so we can provide them to you.

Egg Tray Production: The Need of Automation for Higher Efficiency

Automation is just one way in which we streamline our manufacturing line. If you take this approach even farther, you can think about what automation really is: using Egg tray forming equipment to relieve us of work that we would otherwise have to do by hand. This enables our professionals to manufacture egg trays in a quicker and more error-free way. We will program our machines to work in unison and produce more — egg trays in a shorter cycle. Automation makes us more efficient, and also ensures an egg tray set is safe to use and exactly the same shape every time.

How Equipment Maintenance and Calibration Can Be Used to Maximize Output?

A powerhouse of a manufacturing line, begins and ends with the equipment. This involves checking that our tools are in order and should be done at certain intervals to make sure they run properly. We can avoid breakdowns and delays in our production process by keeping our machines clean and well maintained. We also calibrate our machines so they are producing what we refer to as egg trays. And you do get your egg trays on time, thanks to equipment care management.

Cut Waste and Downtime on Your Egg Tray Manufacturing Line

Waste and down time on WONGS manufacturing line are also something that we work hard to eliminate. Waste, in general, is anything that is discarded or does not serve any purpose. We will use a small amount of materials more accurately and reduce waste during the production process, thereby making more egg cartons with less specified material. Downtime is the time our machines are not working. If we keep our Egg tray making equipment fit and running, we can reduce downtime and stop our production line from halting. We can produce more and waste less, these egg trays Making for you to enjoy.

Improved Worker Training & Communication Leads to Better Production Line Efficiency

We also need our manufacturing line to run smoothly as possible, this involves well trained individuals below are pictures of some of us consulting with a coping jig in one hand and a marker pen in the other. We train our workers; so, they become able to use our machines and produce egg trays properly. Production lines also need good communication.

Table of Contents

- Faster Egg Tray Production with Improved Production Process

- Egg Tray Production: The Need of Automation for Higher Efficiency

- How Equipment Maintenance and Calibration Can Be Used to Maximize Output?

- Cut Waste and Downtime on Your Egg Tray Manufacturing Line

- Improved Worker Training & Communication Leads to Better Production Line Efficiency